The metal lathe is a machine tool which turns a piece of metal on itself while a tool cuts into the material at a preset position. They are equipped with a chuck, which supports the workpieces and rotates at high speed. Operating a lathe can be dangerous as these rotating parts can catch hair, jewelry and clothing. it doesn't take much for a piece of clothing to get caught in and endanger the operator. Flying chips and coolant also present risks for the operator if his personal protective equipment does not protect him effectively.

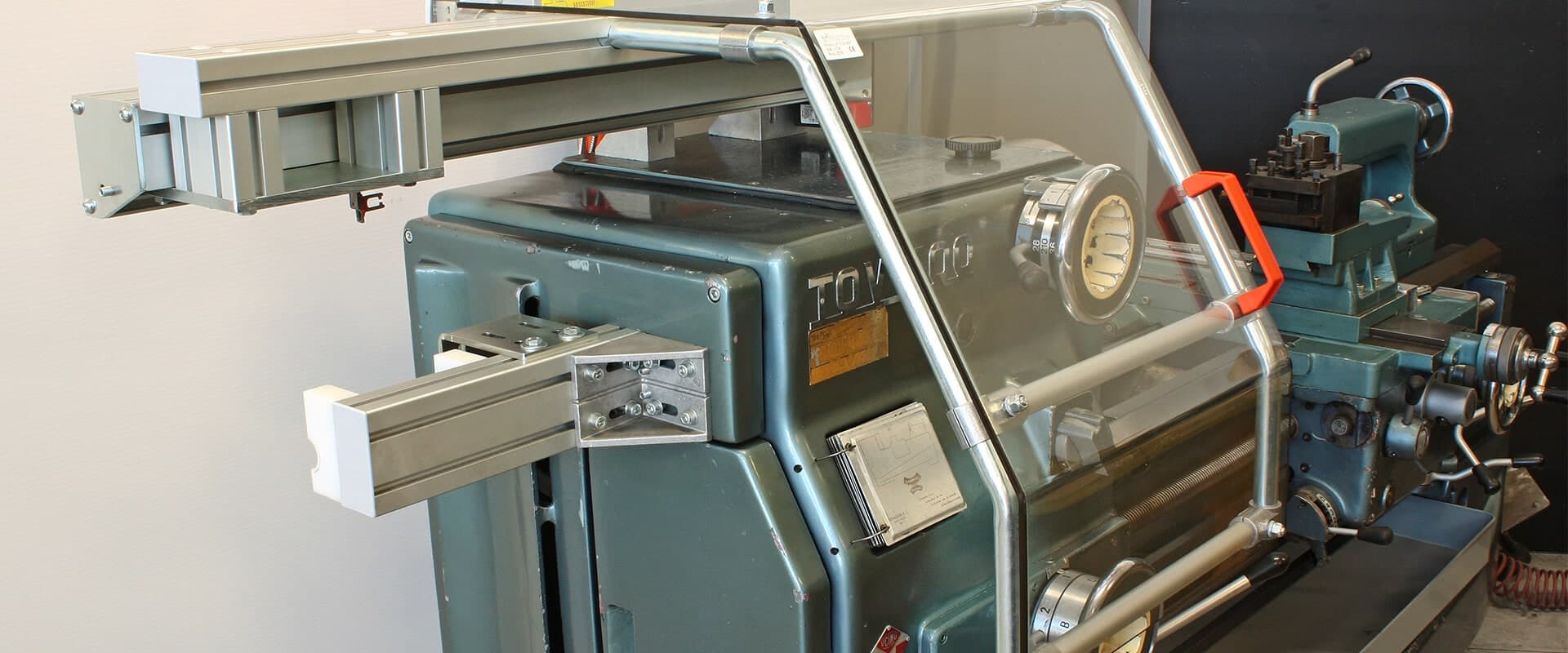

The most well known and used safeguarding method is the hinged chuck-shield, which protects lathe operators from the rotating work-holder. This type of shield prevents an operator from touching the chuck and entangling himself with it, resulting in injuries, asphyxiation or even death. Electrically interlocked shields are the best option, since when the lathe chuck lifts, the microswitch detects it and stops the machine, which will not start up until the emergency stop button has been reset. Workplace safety is a major consideration for Prismont, and for that reason, all our lathe’s safety guards are electrically interlocked using safety microswitches.

There is a second type of safety guard for lathes; the lathe carriage shield. This type of safety guard protects the operator from direct contact with any wastes coming from the cutting tool, such as shavings and lubricant-coolant. Its anti-shaving partition must cover the rotating parts of the lathes such as the lead screw to prevent hair and clothing entanglement.

The lathe’s advancing bars can be very dangerous as well, as work garments can be snagged by them while they move. Lathe lead screw covers are an effective way to protect the operator from it. Made from self-roll up rolls, these tear and oil-resistant bands create a frontal segregation of the lathe mother screw and the advancing bars. When the longitudinal carriage moves, the two units self-roll and unroll, constantly segregating the lathe mother screw and the advancing bars.

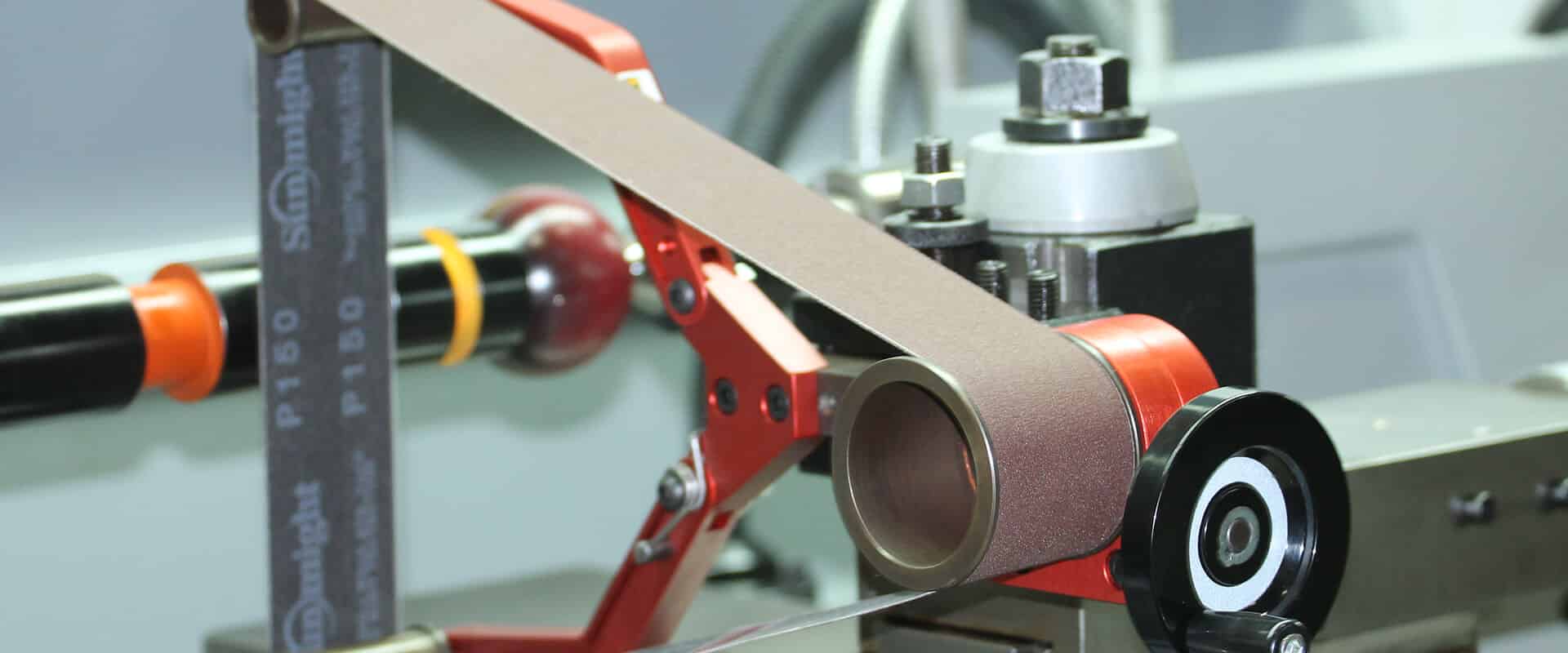

Sanding belt holder for lathes are another new and very interesting way of protecting your operators, as it prevents any entanglement with sandpaper during sanding, deburring or polishing operations on lathes part. Easy to use, this tool allows the operator to sand parts without using his hands, thus keeping hands away at a safe operating distance. By implementing a sanding belt holder for lathes, an employer can make a hands-on machine much safer for operators.

Another great way to prevent injuries when using a lathe is to make operators aware of the safe use of the machine. It will therefore be necessary to remind your employees to:

References

OSHA

Machine Safeguarding at the Point of Operation , A Guide for Finding Solutions to Machine Hazards

https://osha.oregon.gov/OSHAPubs/2980.pdf

Centre canadien d'hygiène et de sécurité au travail

Machines à travailler les métaux - Tours

https://www.cchst.ca/oshanswers/safety_haz/metalworking/lathes.html

IRSST

Dix machines dangereuses

http://www.irsst.qc.ca/media/magazines/V21_04/33-37.pdf

Entraîné dans un tour

http://www.irsst.qc.ca/media/magazines/V21_03/32.pdf