In machine safety, there are stop categories, emergency stop categories, and safety control categories. Each of them categorizes different safety elements, and before exploring emergency stop categories, it is important to make a clear distinction with the other categories.

These categories classify the various parts of safety-related control systems based on their resistance to faults and their behavior following a problem. This is achieved through the structural arrangement of the control system, its level of fault detection, and its reliability (ISO 13849-1:2015).

These two categories are the stop categories that are well defined by standards (emergency stop and normal stop). The emergency stop category is small and is often considered a sub-category of general stops, despite its special characteristics. Emergency stops must comply with different standards, especially regarding the power system and maintenance.

According to the safety norm EN 60204-1 "Safety of machinery – Electrical equipment of machines Part 1: General requirements", there are three categories of stop functions:

These three categories are taken from specific standards such as ISO 13850 and IEC 61800-5-2. According to the ISO 13850 standard regarding the emergency stop function, only a stop category 0 or 1 can be used for an emergency stop. Category 2 is therefore excluded and is a standard stop category. This same standard also allows for defining color codes for buttons, indicators, and wiring markers.

The EN 61800-5-2 standard "Adjustable Speed Electric power drive systems Part 5-2: Safety Requirements – Functional" defines some examples of Safe Stop functions including:

L’arrêt sécurisé 2 diffère de l’arrêt sécurisé 1 en ce sens qu’au lieu d’entrer en STO lorsque le mouvement s’arrête, le système entre en arrêt de fonctionnement sécurisé (SOS). Cela implique que le moteur est amené à une position spécifique et y est maintenu et surveillé par le variateur.

Safe Stop 2 differs from Safe Stop 1 in that, instead of entering into STO when motion stops, the system enters Safe Operating Stop (SOS). During a safe operating stop, the motor is brought to a specific position and held there by the drive. Full torque is available to keep the tooling in position. The stop is monitored safely by the drive.

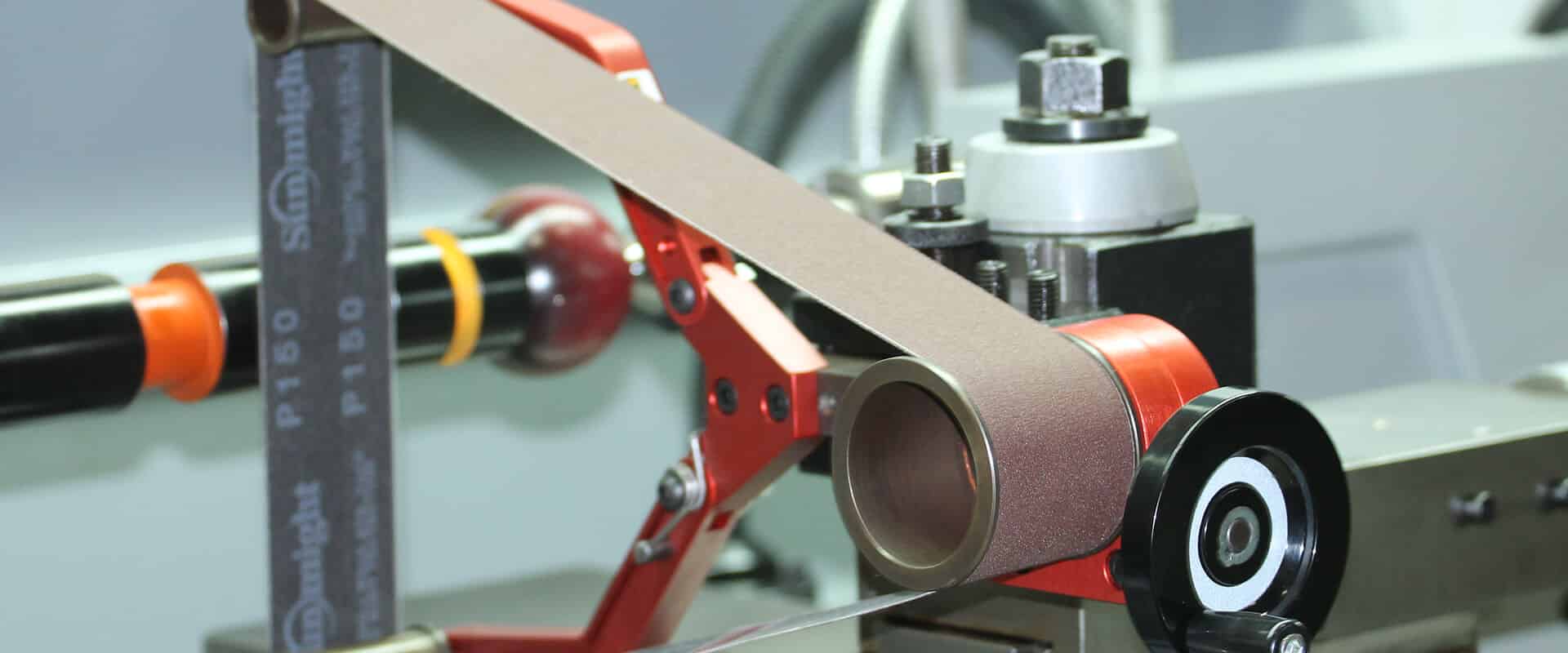

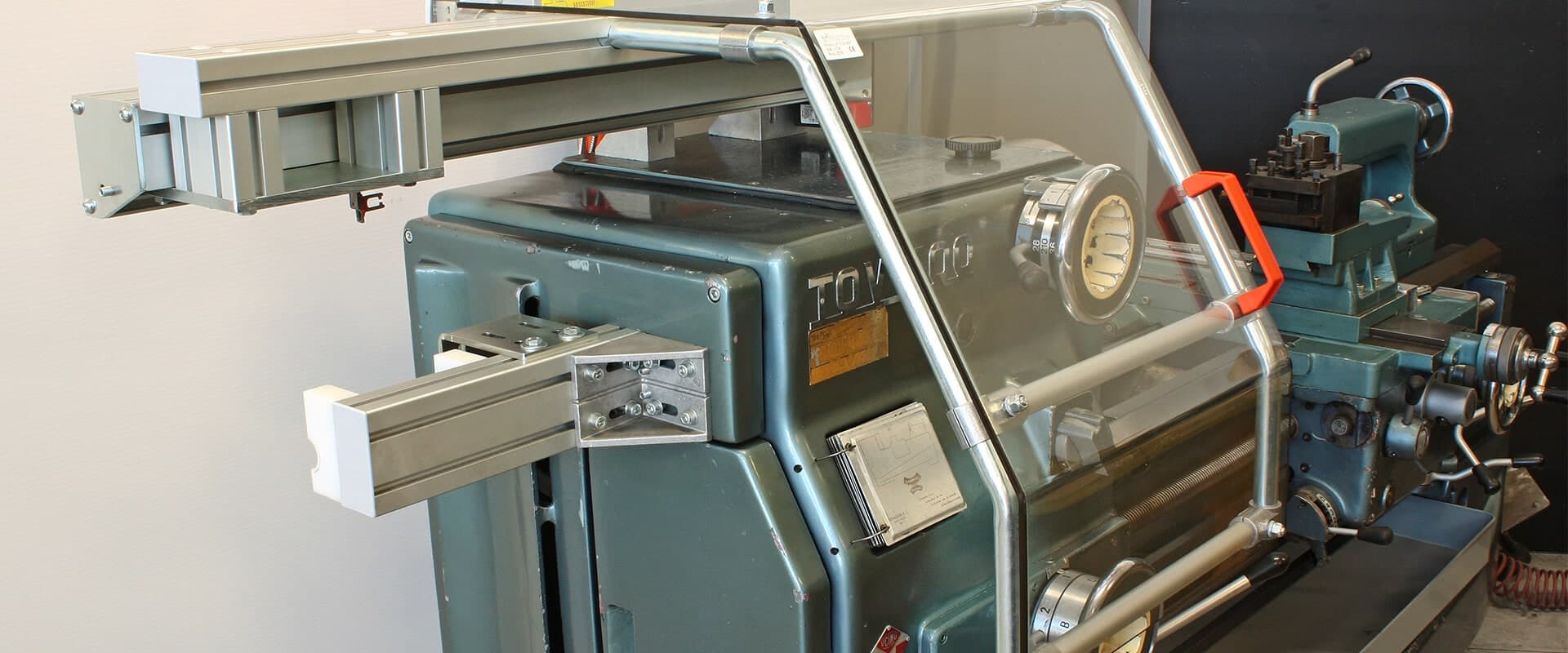

The choice of stop category for your industrial machine should not be taken lightly and will depend on several criteria. In general, machines with moving parts without inertia and whose stop does not pose additional risks will require a category 0 stop. Machines with hazardous parts with inertia or requiring other safety systems typically require a category 1 stop. However, this generalization is not 100% reliable, and it is necessary to consider several pieces of information to make an informed choice.

First and foremost, it is imperative to verify which laws or safety standards govern the use of your machine and the types of stops available. Industrial safety norms and laws vary from one country to another, and it is important to comply with the applicable standards.

Secondly, a risk assessment of the machine and all possible situations must be conducted. The results of this analysis will allow you to choose the perfect stop category that will maximize the protection of your workers without hindering the smooth operation of your business.

Our sales and design team can work with you to determine the appropriate type of stop for your application, taking into account factors such as the application and type of machine, your budget, and applicable laws and standards. Contact us today to start creating a safer workplace.

References

L'écho de Laval

Comment différencier les catégories d’arrêts en matière de sécurité machine?

Intervention prévention