Protecting their workers should be a leading priority for every industrial company. Unfortunately, most employers tend to believe that investing in workplace safety will negatively impact productivity, which couldn’t be further from the truth! Safe working conditions often go hand in hand with ideal operational conditions. Employees can focus on their work and be more productive, instead of trying to avoid dangers in their workplace.

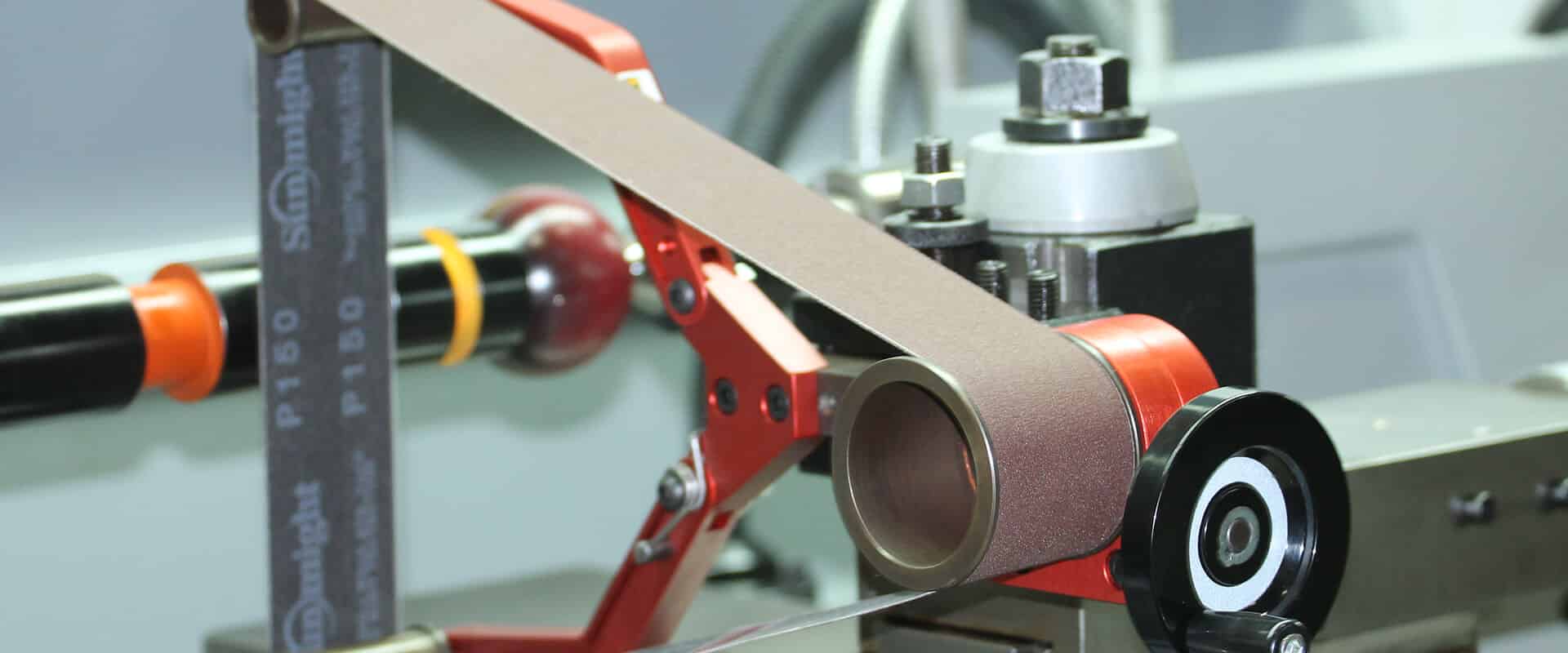

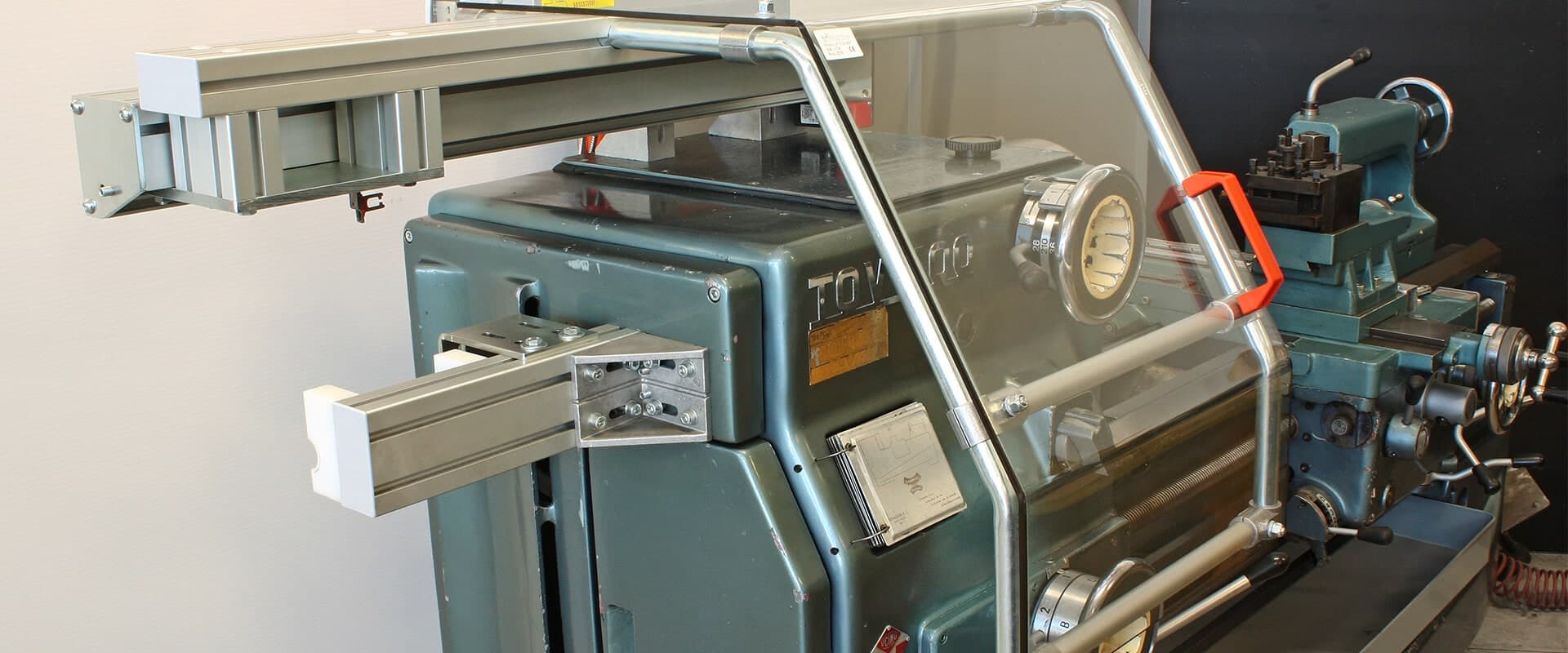

Machinery safety guards and shields are an effective and essential means of protecting your workers, but they should not be the only security solution used. After all, the best way to stay safe is to be able to identify potential hazards and avoid them altogether. This is where the safety signs come in.

Any potential hazards in a workplace should be accompanied by a safety sign to identify it and keep workers from harm. A simple slippery floor can be just as dangerous as a rotating machine part. Safety signs should be placed near the potential source of dangers and be clearly visible. If possible, place them at eye level in a well-lit area. If the place is poorly lit, use phosphorescent colors, reflective materials and / or artificial lighting. Avoid placing an excessive ammount of safety signs near each other to avoid confusion. They must be big enough to be seen and read from afar. It is recommended to use short, clear and concise text on the panels, since the operators tend not to read or only skim the signs with too long instructions. The use of symbols associated with hazards and actions to follow is recommended.

Safety signs must always include:

Simply putting safety signs everywhere in the workplace is not enough. For these safety signs to be efficient, your workers need to be trained to read and understand them. Each sign has a special color and its own symbols. Therefore, your employees must be able to understand which one is which and which security measures are appropriate. Here are some of the things a worker need to learn during safety signage training:

Of course, a safety sign should not replace complete industrial security solutions that comply with the standards. With all the support of the Prismont team, you will benefit from a complete safety solution including a custom design and installation service which comply with all the requirements of the most important conformity and standards

regulations (CSA / OSHA / ANSI / ISO / etc.). We offer a turnkey approach for all services needed including experienced personnel, complete tooling, project planning and scheduling your safety projects large or small.

With an in-depth machine guarding analysis, we can help you identify risks and design a custom safety plan for you to help you deliver optimal Return on Investment (ROI). Contact us today and protect what is most important in your company. votre entreprise.

Reférences

INRS

Signalisation de santé et de sécurité au travail

http://www.inrs.fr/dms/inrs/CataloguePapier/ED/TI-ED-6293/ed6293.pdf

IRSST

Sécurité des machines-outils

http://www.irsst.qc.ca/media/documents/pubirsst/Securite-Machines-outils.pdf

RÉSEAU ICIMÉDIAS

L’importance des panneaux pour la sécurité des machines

https://www.canadafrancais.com/publireportage/limportance-des-panneaux-pour-la-securite-des-machines/