When it comes to investing in workplace safety, the perceived negative impact on productivity is a key concern. The truth is, a safe workplace is often a more productive and profitable one! Safe working conditions often go hand in hand with ideal operational conditions. With safeguards in place, employees can focus on their work, instead of the dangers in their workplace, thus increasing your productivity. You’ll spend less time aiding injured employees and more time creating quality products.

When choosing industrial safety equipment, you can’t compromise on your employee’s safety. Safety equipment can sometimes be very expensive. It is therefore crucial to ensure that your purchase generates an optimal return on investment (ROI).

Machine safeguarding can help businesses increasing ROI and reduce operating costs by eliminating costs of accident. But what are these potential costs?

Direct costs are the costs recorded in the company's accounting system as a result of accidents. Any expense and loss of productivity due to work-related accidents are considered direct costs. They may include costs for repairs, hospitalization and medical expenses, but also workers' compensation, the purchase of new equipment, and a temporary closure of other machines. The bills can quickly accumulate for a single accident.

Contrary to popular belief, the costs of a work accident do not stop there. Analysis showed that the indirect costs are often 4 times higher than the direct costs. Indirect costs are the losses incurred by the company as a result of an accident at work, but which are not counted as such. They may include professional health care, victim follow-up, lost productivity, study costs following the accident, human resources, hiring costs, legal aspects, training, and more.

After an accident has occurred, fines and insurance costs often increase, leading to recurrent thicker bills. Legal fees and litigation costs can be very high in an accident resulting in the death or injury of an employee. In such cases, the costs can be unlimited and are even higher when a machine has been poorly protected. The lawyers' fees can then accumulate and the growth investments of the company must be diverted to cover these legal costs. In other words, you will spend far more on lost wages, productivity and legal costs than you would have needed to invest in securing your factory properly.

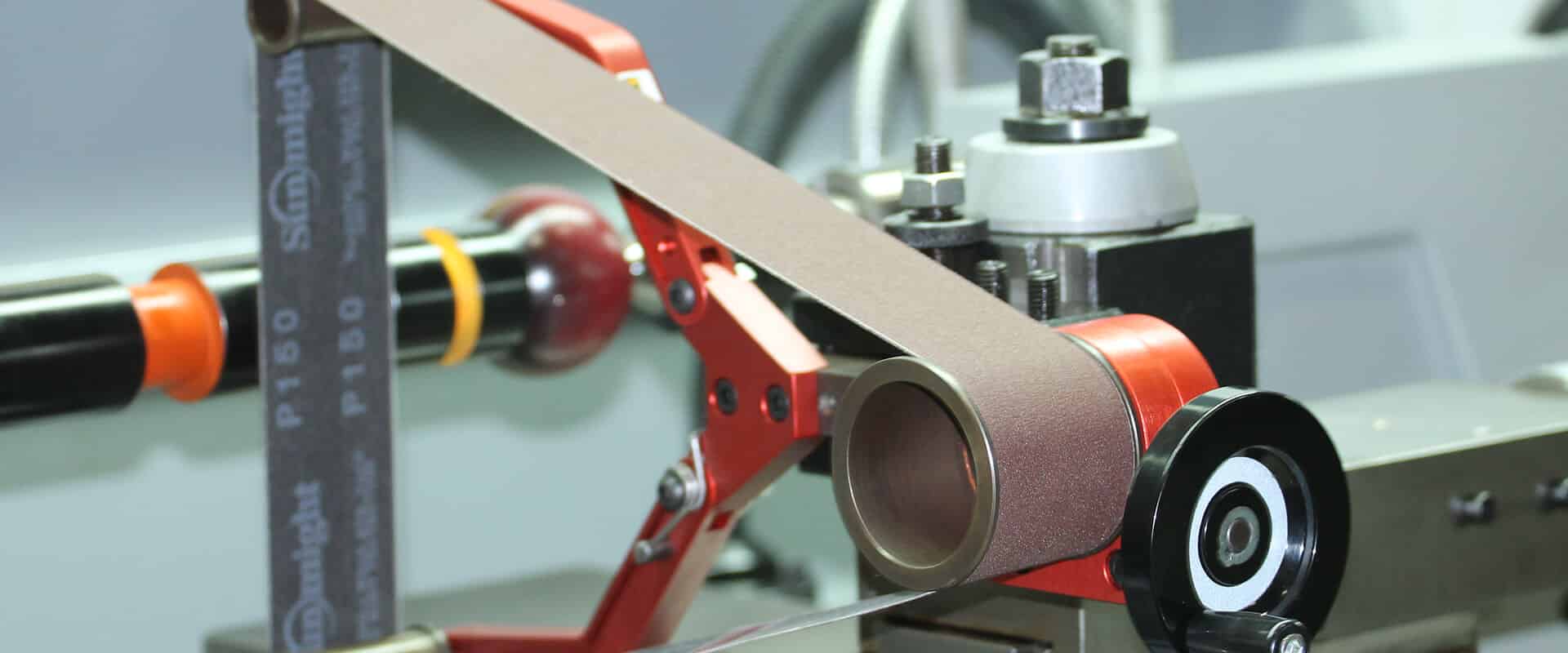

To ensure safe operator use, machines must be protected using safety guards and devices. Any machine part, function or process that may cause injury must be protected to prevent crushing of hands and arms, finger fracture, blindness or other potential injury.

In order to properly maximise employee safety, you need to ensure that they can easily identify and avoid potential hazards. An efficient way of doing so is by using safety signs, which will help prevent injury to both employees and public which might be around a certain hazard. By learning that the floor is slippery, or that a certain part of a machine may move, they can be more cautious and act accordingly. Any potential hazard must be accompanied by a safety sign to warn workers and keep them from harm. They must be placed near the source of danger and be clearly visible.

Sometimes, improperly using a machine is just as dangerous as using an improperly safeguarded machine. Properly training them on machinery usage et appropriate safety measures ensures that workers will be able to use the machines and safety equipment in the safest way possible, the way they were designed to be.

Your employees’ safety should never be compromised, and a safety analysis is your first step in identifying your risks and implementing the perfect safety solution for your business. For years, we’ve helped industrial workplaces become safer and more productive through customized safety solutions. Our sales and design team can work with you to determine the type of safety guards that will fit your application, taking into account factors such as how often you need access to the machinery, how much space you have to work with and the budget for the project. Contact us today to get started on creating a safer workplace.

References

IRSST

Analyse des avantages et des coûts de la santé et de la sécurité au travail en entreprise

https://www.irsst.qc.ca/media/documents/PubIRSST/R-375.pdf