Versatile and precise, lathe operations are a staple in factories and machining operations. Turning is a machining process where a piece is rotated while a cutting tool removes material to achieve the desired shape. Performed on a machine tool called a lathe, turning allows for the creation of symmetrical parts relative to an axis, such as shafts, cylinders, or cones.

Commonly practiced in metalworking industries, sanding operations complement machining. This type of operation polishes/smooths the surface of a part, removes rust, or corrects defects. This results in a clean part with a smooth, polished finish, which can be crucial during part manufacturing.

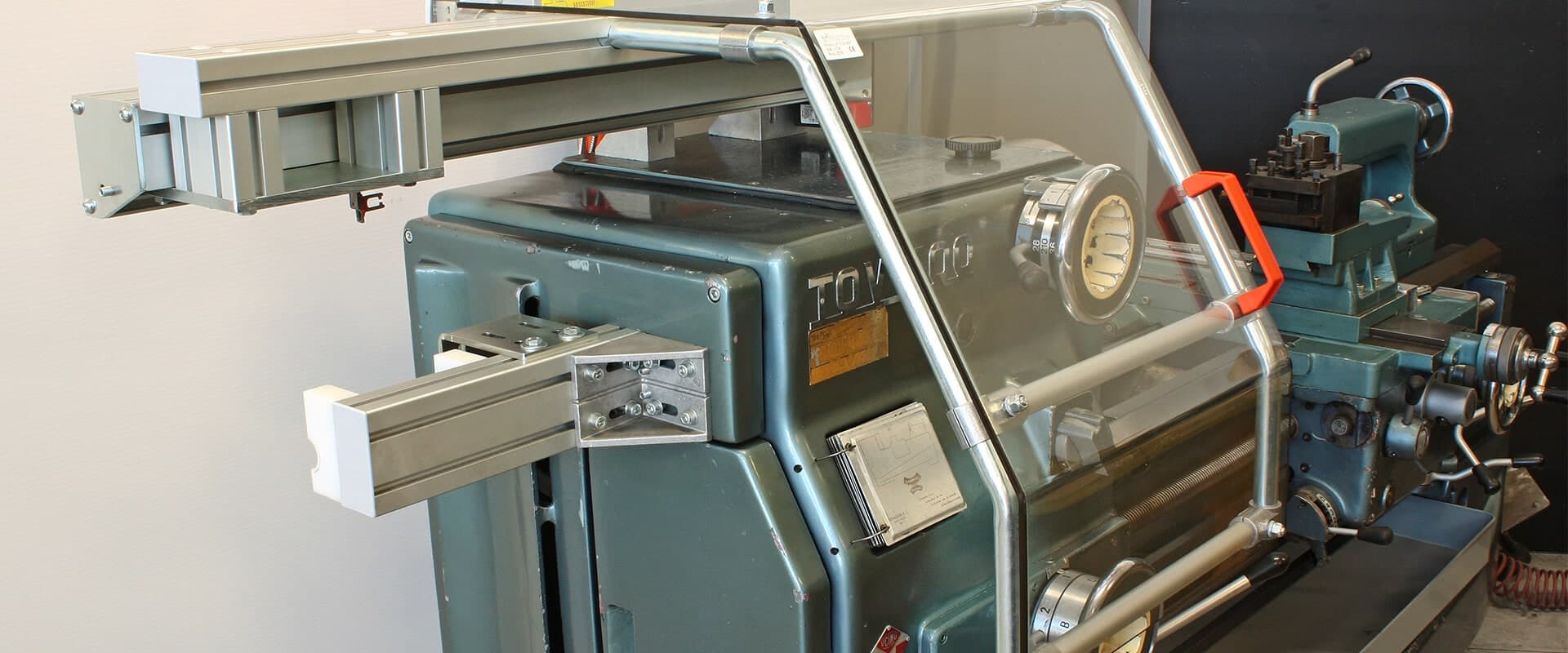

In the past, operators polished and sanded lathes manually using emery cloth and sandpaper, or abrasive paper. A strip of emery cloth was held between both hands and wrapped around the back of the rotating part. However, this method carries significant risks, and more effective solutions now exist, such as using a sanding belt holder for conventional, numerical or metal lathes.

A large number of accidents on metal lathes are caused by using emery cloth and sandpaper. Handheld tools and emery cloth give a false sense of security. The cloth can easily get caught on the workpiece, wrap around fingers, and pull the operator's hand into the rotating machinery, leading to fractures, crush injuries, lacerations, amputations (especially fingers), and even death.

Beyond the risk of entanglement, the repetitive motions of manual polishing are physically demanding, contributing to strain and other musculoskeletal problems over time. Additionally, operators are at risk of being hit by flying metal particles. Manual sanding operations also doesn’t guarantee effective results, as it’s common to apply uneven pressure, resulting in inconsistent finishes.

To avoid the risks associated with manual sanding on conventional lathes, it is recommended to use a dedicated tool specifically designed for sanding and polishing on lathes. This method allows for sanding without an operator near the rotating parts or using their hands. It is also recommended to wear fitted work clothing and avoid wearing gloves or jewelry near rotating parts.

Do the operators of your conventional lathes use their hands to sand, deburr, or polish the rotating surfaces of the lathe? Manual sanding on lathes can be extremely dangerous for both operators and their work environment.

In addition, Prismont lathe sanding tools are available for a variety of conventional lathes and parts different sizes, making them versatile and suitable for various production needs. The set attaches to your existing lathe tool holder, allowing for easy installation and removal.

During sanding operations, abrasive particles are propelled at high speed onto the surface of the workpiece. These particles can be inhaled by operators, leading to respiratory issues and long-term lung damage.

The sanding process generates significant forces that can result in the projection of abrasive particles or material splinters. These projections can cause serious injuries to operators if they are not wearing proper protective equipment.

Some types of abrasive materials used in manual sanding may contain hazardous chemicals. Exposure to these chemicals can lead to skin irritation, burns, or other health issues.

If sanding is not performed with precision, it can damage the surface of the workpiece, resulting in defects or imperfections that can compromise its functionality or durability.

Sanding and polishing generate abrasive waste that must be properly disposed of to prevent environmental pollution. Some abrasive materials can also be toxic to soil and groundwater if not properly managed.

To minimize these dangers, it is important to follow strict safety procedures, provide operators with appropriate personal protective equipment, and use safe abrasive materials and sanding techniques that comply with current regulations.

By eliminating the need to use hands in the work area, the MST-SBH lathe sanding tool significantly reduces the risk of entanglement. This protects operators and reduces corporate liability.

Unlike manual methods, which depend on the pressure, skill, and irregular movements of the operator's hand, the MST-SBH lathe sanding tool allows control of the sanding speed, pressure, and angle. This ensures a precise and uniform finish on each part, regardless of the operator. Additionally, the MST-SBH enables repeatable finishes on similar parts, which can be important for mass production applications.

Using our lathe sanding tool can speed up the finishing process, allowing for high-quality finishes in less time than if done manually. This allows for more parts to be processed in less time, increasing productivity. Additionally, this tool reduces physical fatigue that operators may experience during manual polishing, enabling the operator to be more efficient.

Although the initial investment in a lathe sanding tool may seem higher than the cost of manual sanding, the long-term savings are significant. In addition to reducing errors and scrap, the tool helps reduce downtime due to human fatigue and accidents. Moreover, the longevity of parts treated with a uniform, high-quality sanding is often improved, reducing maintenance and replacement costs in the long term.

Our lathe sanding tools are designed to be versatile and available in different grits and sizes. They can be used on a wide variety of surfaces and materials, making them essential for shops handling different types of parts and looking to reduce tool replacements.

The dangers of using hands when operating a lathe cannot be overstated. Switching from manual sanding to a conventional lathe sanding tool offers many advantages: time savings, increased productivity, better finish quality, and reduced risks for your employees. In the long run, this automation can not only improve the quality of your production but also provide substantial savings. Prioritize the safety and well-being of operators while achieving superior finishes. The investment is worth it.

Not sure which sanding tool you need, or need to secure your conventional lathe with safety equipment? Our sales and design team can work with you to determine the right safety device for your application, considering factors such as machine access frequency, required space, and project budget. Contact us today to start creating a safer workplace.

References

INRS

Toilage manuel sur tours – Comment travailler en sécurité, ED 6243, INRS, 2016

Brochure ED 6122 - «Sécurité des machines - Prévention des risques mécaniques»

Brochure ED 6243 - «Toilage sur tours horizontaux, comment travailler en sécurité ?»

Opérations de toilage sur tours horizontaux

Carsat et L’Assurance Maladie - Risques professionnels

Guide explicatif des exigences réglementaires à l'intention des milieux de travail

Réglement sur la santé et la sécurité du travail

Amélioration de la sécurité des machines par l’utilisation des dispositifs de protection

Amélioration de la sécurité des machines par l’utilisation des dispositifs de protection

EN.12840-2001 & ISO 23125:2010 Safety Norms