Price range: USD $845.00 through USD $2,895.00

Designed and manufactured in Canada, the PRISMONT lathe sanding tool is an original machine safeguarding solution that ensures safe and precise sanding, polishing, and deburring operations on lathes. Engineered to protect operators, it eliminates the risks of manual hand sanding on conventional or CNC lathes. This industrial-grade device is available in two versions: the MST-SBH standard manual mode and the MST-SBH(A) manual mode with belt clutch control, offering enhanced rotation control. Each device comes with 3 abrasive belts for immediate use.

Demonstration of the Manual Mode – Model MST-SBH

Demonstration of the Manual Mode with Belt Clutch Control – Model MST-SBH(A)

The Prismont MST-SBH external lathe sanding device is designed to provide operators with safe, efficient, and precise finishing operations directly on machined parts—without the use of hands. Attached to the conventional lathes existing tool post, this tool securely holds abrasive belts for a variety of applications such as sanding, polishing, finishing, and deburring on metal, alloy, or wood parts during turning operations.

Compatible with both conventional and CNC lathes, the MST-SBH improves surface quality while reducing the risks associated with manual hand sanding. It eliminates the hazards of using improvised tool holders, ensuring increased operator safety and consistent finishing results.

Its ingenious design allows for:

The MST-SBH is available in two versions to meet different production needs:

Each device comes with three abrasive belts included, allowing for immediate use. In addition, this device is designed in compliance with international standards EN 12840:2001 and ISO 23125:2010, which govern the safety of machine tools, ensuring conformity with globally recognized industrial standards.

Made and designed in Canada, this product is an original product by PRISMONT. Trust the original product and avoid copies.

MST-SBH | A safety way for sanding

MST-SBH(A) | Manual Sanding Belt Holder with belt clutch control for Lathes

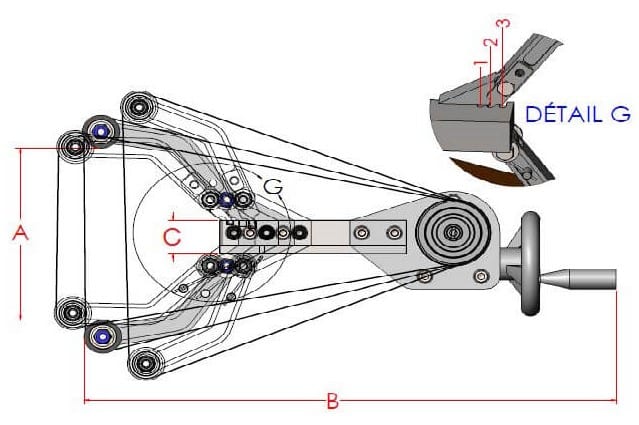

The technical diagram illustrates the main dimensions of the sanding device:

| CODE | Name | Mode | Max.Ø | A | B | C | Belt |

|---|---|---|---|---|---|---|---|

| MST-SBH1.0 | Lathes Sanding Belt Holder – 1″ × 30″ | Manual | 150 mm 6 “ |

160 mm 6 1/4″ |

325 mm 13″ |

19 mm 3/4″ |

25 × 762 mm 1″ × 30″ |

| MST-SBH2.0 | Lathes Sanding Belt Holder – 2″ × 36″ | Manual | 200 mm 8″ |

215 mm 8 1/2″ |

350 mm 14″ |

19 mm 3/4″ |

50 × 915 mm 2″ × 36″ |

| MST-SBH4.0 | Lathes Sanding Belt Holder – 4″ × 54 | Manual | 300 mm 12″ |

330 mm 13″ |

400 mm 16″ |

25 mm 1″ |

100 × 1372 mm 4″ × 54″ |

| MST-SBH4.0EX | Lathes Sanding Belt Holder – 4″ × 71″ | Manual | 500 mm 20″ |

550 mm 22″ |

500 mm 16″ |

25 mm 1″ |

100 × 1800 mm 4″ × 71″ |

| MST-SBH(A) 1.0 | Manual Lathes Sanding Belt Holder with Belt Clutch Control – 1″ × 30″ | Manual with belt clutch control | 150 mm 6″ |

160 mm 6 1/4″ |

325 mm 13″ |

19 mm 3/4″ |

25 × 762 mm 1″ × 30″ |

| MST-SBH(A) 2.0 | Manual Lathes Sanding Belt Holder with Belt Clutch Control – 2″ × 36″ | Manual with belt clutch control | 200 mm 8″ |

215 mm 8 1/2″ |

350 mm 14″ |

19 mm 3/4′” |

50 × 915 mm 2″ × 36″ |

The two series of models operate differently. The MST-SBH series is the device with the standard manual operating mode. It includes models MST-SBH1.0, MST-SBH2.0, MST-SBH4.0, and MST-SBH4.0EX. The MST-SBH(A) model uses a manual operating mode with belt clutch control for greater control of rotation. It has no motor. It includes models MST-SBH(A)1.0 and MST-SBH(A)2.0.

The compact models MST-SBH1.0 / MST-SBH(A)1.0 are suitable for diameters up to 150 mm (6″), the intermediate MST-SBH2.0 / MST-SBH(A)2.0 up to 200 mm (8″), the MST-SBH4.0 up to 300 mm (12″), and the MST-SBH4.0EX up to 500 mm (20″). The technical specifications table above serves as a useful reference.

The lathe sanding device is suitable for both conventional and CNC lathes. It can be used on metal, alloy, or wood parts during turning operations.

In stock : Yes

Lead Time to Ship : 3-5 Business Days