Secure your lathe operations with PRISMONT lathe safety guards and sanding and polishing tools designed for industrial machining. Our product range includes electrically interlocked safety guards for conventional and CNC lathes, as well as original sanding tools designed and manufactured in Canada, delivering improved safety, visibility, and productivity in industrial environments. Regardless of your lathe size, PRISMONT offers a safety guard designed for your machine.

A lathe is a machine tool used to rotate workpieces for operations such as turning, threading, drilling, and cutting. Widely used in industrial workshops, manufacturing facilities, and technical training centers, lathes can be conventional or CNC, depending on the required level of automation.

Due to high-speed rotation, exposed chucks, and frequent operator intervention near the machining area, lathes require proper machine guarding solutions designed to protect operators without compromising precision or productivity.

Properly securing a lathe helps reduce risks while maintaining an efficient and productive work environment. Modern machine guarding solutions provide a significant improvement over improvised or partial protections, which are often insufficient in industrial settings.

PRISMONT lathe safety guards are all electrically interlocked and help:

These solutions comply with recognized machine safety standards such as OSHA, ANSI, ISO-EN, and CE, and integrate seamlessly into modern industrial practices.

Lathe operations expose operators to several common hazards, including:

PRISMONT’s approach focuses on providing proven, practical solutions that effectively secure these areas while maintaining smooth and uninterrupted workflow.

PRISMONT offers a complete range of electrically interlocked lathe guards, designed to protect different parts of the machine depending on the application:

Each guard is designed for direct installation on existing lathes, with simple adjustments and reliable integration, whether on new or existing machines.

Replacement safety shields are also available to extend equipment life and maintain a high level of protection over time.

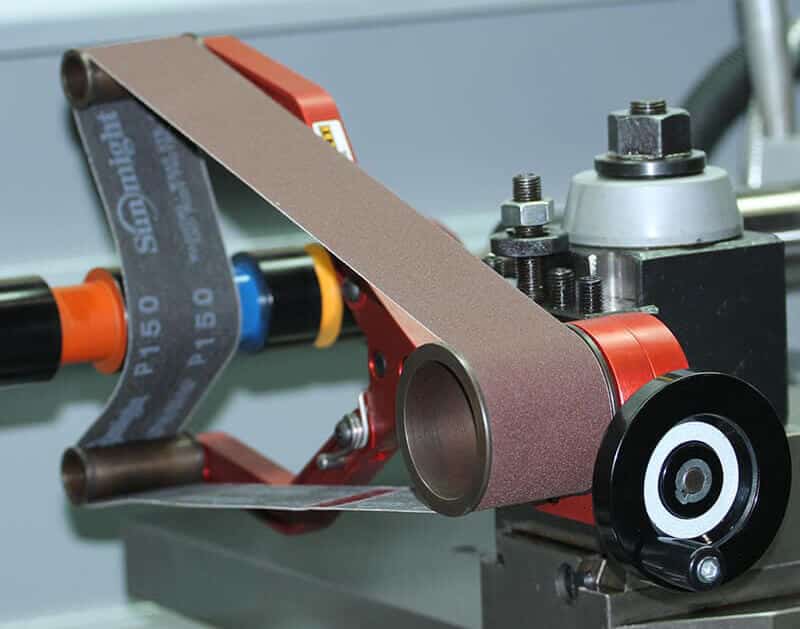

In addition to machine guarding, PRISMONT offers sanding, belt sanding, and polishing tools for lathes, used directly during turning operations to improve surface finish quality.

Designed to replace manual sanding, these tools allow sanding, deburring, and polishing operations to be performed without hand contact, providing a safer, more stable, and more precise solution for operators.

PRISMONT sanding tools are designed and manufactured in Canada and installed directly on existing lathe tool post, making integration quick and straightforward. Developed for industrial use, they comply with international standards EN 12840:2001 and ISO 23125:2010, helping improve safety, finish consistency, and productivity.

PRISMONT offers several lathe sanding and polishing tool models, designed for both external and internal machining applications.

The MST-SBH lathe sanding belt holder is designed for sanding, belt sanding, polishing, and deburring operations on the external surface of rotating parts. It delivers stable, uniform results with excellent pressure control.

Available in multiple sizes, the MST-SBH adapts to a wide range of part diameters and working conditions. The MST-SBH(A) version integrates a belt clutch control mode to improve rotational control during finishing operations.

The MST-IPA lathes Inside Polishing Attachement is specifically designed for polishing, light grinding, belt sanding, sanding, and deburring inside hollow parts, such as tubes.

Its design allows access to hard-to-reach areas while maintaining high levels of precision and operator safety. Available in various lengths, diameters, and power levels, the MST-IPA suits a wide range of industrial applications, from production workshops to technical training environments.

PRISMONT also offers a complete range of abrasive accessories designed specifically for its sanding tools, including:

Available in various grits and dimensions, these accessories allow precise adjustment based on the application and desired surface finish.

Choosing the right safety guard or sanding tool depends on several factors:

PRISMONT provides solutions for a wide range of industrial applications, helping secure lathe operations without compromising performance.

PRISMONT solutions are designed to integrate seamlessly into industrial environments, with a strong focus on operator safety, equipment durability, and production continuity.

Whether for a production shop, training facility, or advanced CNC environment, PRISMONT delivers reliable, proven lathe safety guards and finishing tools designed for industry.