On Request! Stock-ready stainless steel modular guards for chemical and food industry. Our Guard fencing system INOX is realised using Stainless Steel and materials which are long-lasting, cleanable, disinfectable, fissurefree, splint-free and rough-ends free.

Our Guard fencing system for machinery employed in the food industry and the chemical industry is realised using Stainless Steel and materials which are long-lasting, cleanable, disinfectable, fissurefree, splint-free and rough-ends free.

This system has been designed in compliance with standard UNI EN 1672 in order to seek the ever better compromise between hygiene requirements and operator safety issues.

Access’s catalogue offers two solutions which have been designed for the SPLASH Area type SH and NO FOOD Area type NF. Both solutions integrate the requirements in terms of hygiene risk and machinery risk prevention as outlined in the following standards: UNI EN ISO 12100, UNI EN ISO 13857, ISO 14120 and ISO 14159.

| Zone | Raw Material | Finishing | Tubular frame | Mesh | Assembly | Frame welding | Sealing caps | Tubular fixing brackets | Base plate | Bracket fixing kit | Bracket cap |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Area Splash type SH | Raw Material INOX AISI A 304 | Finishing by mechanical polishing | Tubular frame 25 x 25 x 1,5 mm without screw housings | Anti-finger trapping mesh TEC mesh 15x105 mm thread 3,0mm | Assembly with mesh clamps in plastic suitable for food applications | Frame welded with TIG and finished with abrasive carton grinder | Sealing caps in plastic suitsble for food applications | Profiled and raised base plate to allow liquid drainage | Profilée et rehaussée pour l’écoulement des liquides | META® fixing kit with rounded head screws | META® cap with special profile |

| Area No Food NF | Raw Material INOX AISI A 304 | Finishing by mechanical polishing | Tubular frame 20x20x1,5 mm sans trous pour les vis | Mesh 40x40 mm thread 3,0 mm | Assembled with electro – welding without soldering material | Frame welded with TIG and finished with abrasive carton grinder | Sealing caps in plastic suitsble for food applications | Tubular fixing brackets 40x40x1,5 mm with no housings | Profiled and raised base plate to allow liquid drainage | META® fixing kit with rounded head screws | META® cap with special profile |

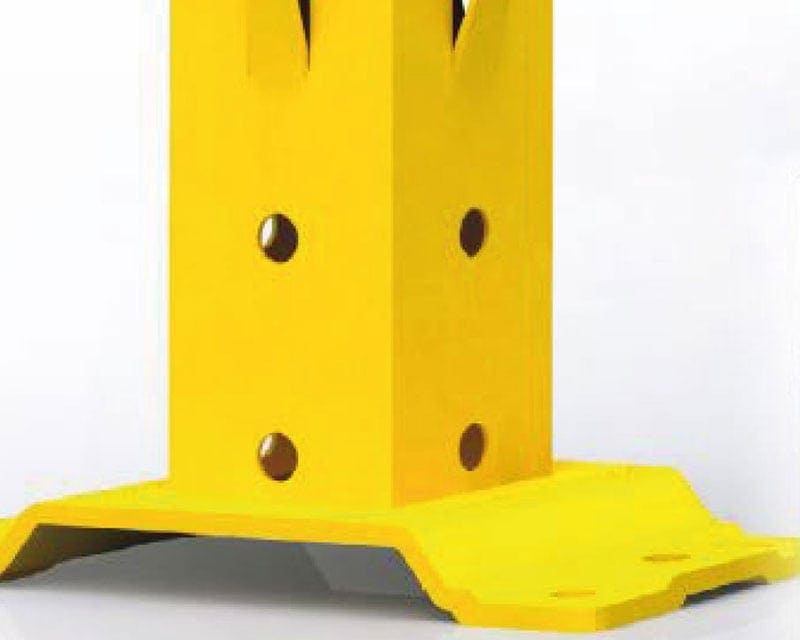

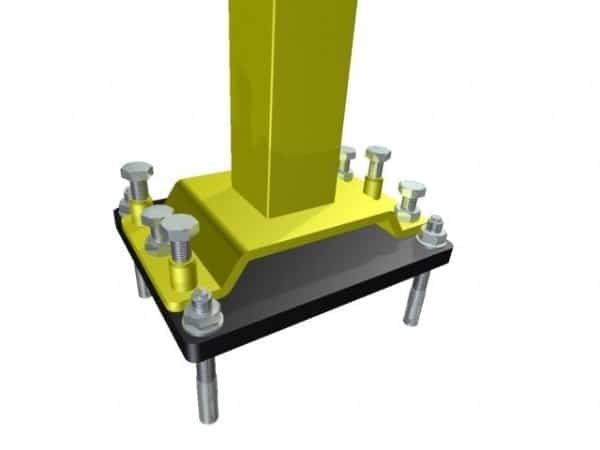

Economical fixing system for perimeter protection fencing and modular guards with universal welded base, simple and fast installation and CE certification. Access has designed and engineered Meta® brackets (European patent No. 2226451) in conformity with the UNI EN ISO 14120 (already EN 953), EN 12100 Standards and the Machinery Directive 42/2006, Meta® brackets meet all the requirements in terms of design and manufacturing of work area guard systems therefore they can be used as an essential fixing system for all CE certified mobile guards. Access Meta® unbeatable fixing bracket system is supplied with plugs for floor fixing with welded plate base.

| Height | Width | |||||||

|---|---|---|---|---|---|---|---|---|

|

60 x 60 mm 2 23/64" x 2 23/64" |

1620 mm 63 25/32" |

2020 mm 79 17/32" |

2520 mm 99 7/32" |

|||||

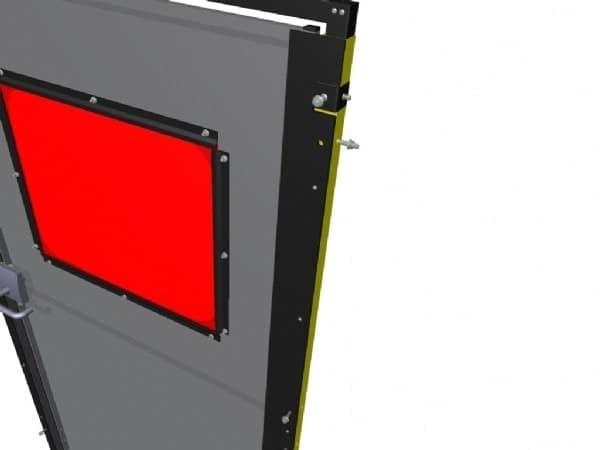

Discover a wide range of Access “Door-in-a- box” kit. Each door is supplied separately and can be fitted on any Access frame in any position. Access offers a wide range of kits to transform standard panels into practically any type of door according to specific needs:

We are able to supply a variety of customised special doors to meet customer needs by mixing and matching all door components according to specfic requirements such as:

We are able to design and manufacture automatic doors for special industrial applications in which maximum safety needs to be granted by segregating working areas when machinery is running, or simply there is a need to manage mobile guards opening/closing for product loading/unloading.

Access doors can be designed to be controlled by a pneumatic cylinder, a chain or cable transmission electric motor or linear units and are fitted with the a ppropriate mobile guard safety de vice as prescribed in the following sta ndards: ISO 14120, ISO 14119, ISO 13855, ISO 13856.

Doors are equipped with a control cabinet which can be fitted with optional features such as a safety control unit, an inverter for electric motors, radio frequency devices interfacing the production line PLC.

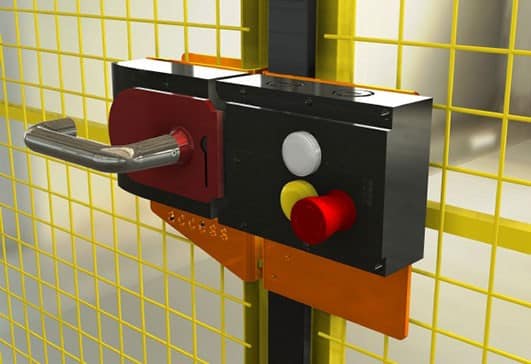

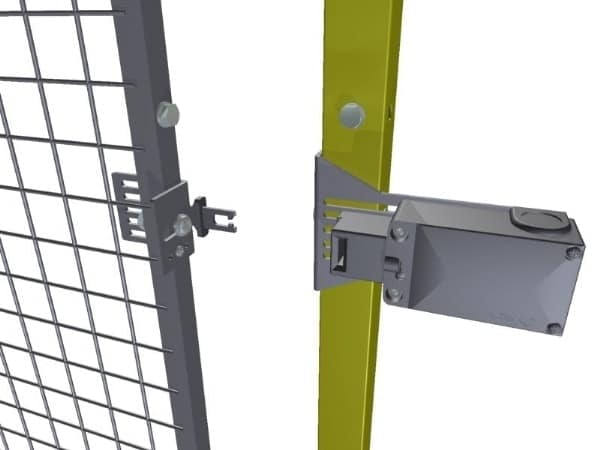

Control dangerous zones’ access using our control systems compliance and locks.

The door locking systems have been designed to reach the perfomance level (Plr) required by the risk analysis as outlined by ISO 13849 standard (Safety Control system components – part 1 : General design principles) in order to meet the ISO 14119 requirements in regards to tampering prevention.

We offer a number of standardized solutions to solve the most common risk cases.

In case of emergency, all locking systems can be opened manually from the inside and are designed to fit housings for personal padlocks which prevent incidental closing and therefore the risk of machinery restarting while workers are still present in the danger area.

Standards references: UNI EN ISO 12100, UNI EN IS O 13849, UNI EN ISO 14119, CEI 62061.

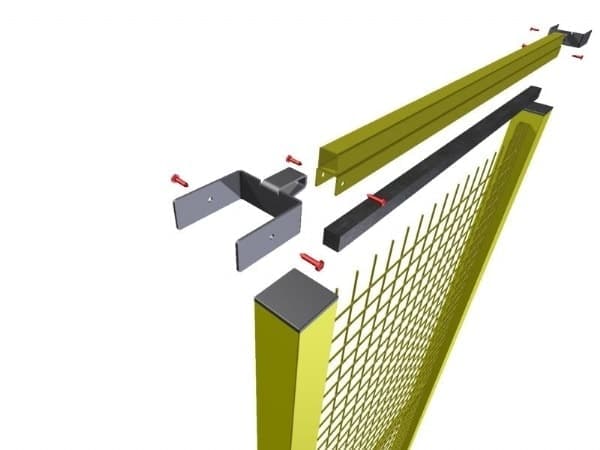

Access optional kits cater for all mounting needs and/or integrate the guard fencing systems with machinery and sensors support components.

Panel height reshaping kit

Panel width reshaping kit

Bracket kit for panel installation at different floor levels

Adjustable push and pull plate for standard posts

Universal Bracket for microswitch and actuator installation

Pack of fixing screws for panel to panel connection, available for 20×20 mm and 30×30 mm frames

Equipotential protection circuit kit for grounding compliant with IEC 60204

Bracing kit with set of fixing components

Fixing components (brackets and screws) Cable Chain support edge

Cable tray bracket

Rubber buss bar with fixing components

Bracket-less fixing system in compliance with UNI EN ISO 14120

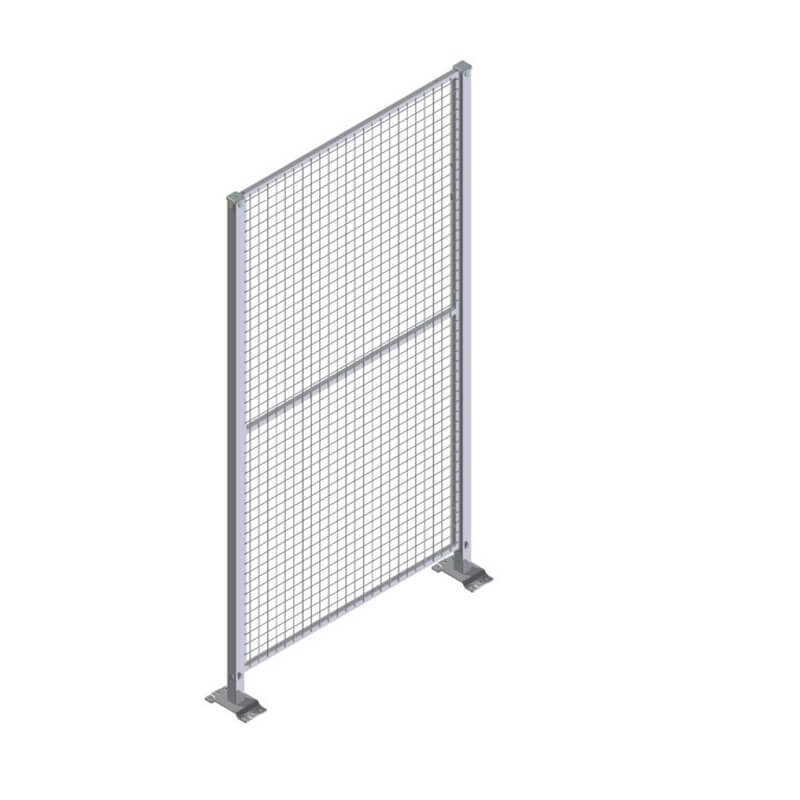

Our complete range of perimeter protection are perfect for the protection of robotic workspaces, areas where the movement of machines is potentially dangerous or storage spaces with restricted access. Flexible and 100% compliant with ISO and CE standards.

Discover how to assemble our Meta fixing brackets. This economical fixing system is CE, UNI EN ISO 14120, EN 12100 and Machinery Directive 42/2006 certified.

Our mesh panels are subjected to a large array of tests. Among them, we find the pendulum test used to test the resistance of protection systems to impacts.

Quickly connect the modular panels of your protection fencing to each other using these fixing screws kit for panel to panel assembly tutorial.

Learn how to install our bracket kit for mesh panels at different floor levels.

Quickly assemble and install the ISO 14120 captive screws of our mesh panels.

Assembling a single leaf door has never been so easy! This mesh door is part of a wide range of “Door in a box” door kits. They are sold separately from panels to meet all requirements and can be mounted on any Access chassis.

Assemble and quickly install the single sliding door of your PENTA Modular Panels. Easy to install, this door is part of our “Door in a box” kit, which doors are sold separately from the panels to meet all the requirements of your factory and offer greater flexibility.

Do not waste time thanks to our telescopic single door assembly tutorial. Easy to install, this door is sold separately from our modular panels, offering greater flexibility for the protection of hazardous areas of your factory.