Protect your operators with PRISMONT’s range of bench grinder safety guards, designed to improve visibility and reduce exposure to sparks, abrasive debris, and grinding wheel fragments. We offer universal safety shields, compact frontal guards, and advanced interlocked models to meet different safety requirements. Easy to install and adjust, these solutions integrate perfectly into industrial workshops and grinding stations.

A bench grinder is a machine tool equipped with rotating abrasive wheels used for sharpening, grinding, deburring, or polishing metal workpieces.

Commonly found in mechanical shops, machining facilities, maintenance departments, and manufacturing environments, bench grinders are simple yet essential tools. Their speed and versatility make them widely used on a daily basis.

However, like any machine with exposed rotating components, bench grinders require proper safety guarding to secure the work area.

To safeguard a bench grinder effectively, it is important to focus on the machine’s main exposed zones:

Grinding wheels are the essential rotating components of the grinder. They generate sparks, abrasive projections, and sometimes fragments during grinding or sharpening operations.

The shaft is the central axis around which the wheels rotate. This constantly moving area must be properly protected.

Safety shields, spark arresters, and industrial bench grinder guards help reduce exposure to flying debris while maintaining clear visibility of the work zone.

Adding the right guard significantly improves operator safety without reducing precision or comfort.

Selecting the proper guard depends mainly on three criteria: the required safety level, workstation configuration, and ease of adjustment.

In certain industrial environments or compliance audits, an interlocking system may be required.

An interlock is a safety device that prevents the grinder from operating when the guard is open or improperly positioned. This reduces accidental risks and strengthens machine safety compliance.

Interlocked protection is especially relevant in contexts that are:

Depending on your workplace, a standard guard may be sufficient, while interlocking is recommended for higher-risk stations.

The MST-MA11 includes an integrated interlocking system and complies with OSHA, ANSI, ISO-EN and CE standards, making it ideal for demanding industrial environments.

For standard needs where interlocking is not required, the MST-MA02 and MSB-GA10 provide reliable and effective protection.

Your bench grinder setup directly influences which guard is best. Consider the following:

A well-chosen guard should integrate naturally into the workspace without reducing visibility, comfort, or accuracy.

Quick adjustment improves usability and allows protection to adapt to the size and type of workpiece.

The MST-MA11 offers maximum flexibility thanks to its multi-adjustable hexagonal arm, while the MST-MA02 focuses on simplicity and fast everyday positioning.

Depending on your safety requirements, workstation layout, and operating environment, each PRISMONT solution answers a specific need.

The MST-MA11 is a dual safety guard designed for demanding industrial applications. Its multi-adjustable hexagonal arm ensures precise positioning and excellent stability.

Its integrated interlocking system cuts power when the guard is open or misaligned, ensuring compliance with OSHA, ANSI, ISO-EN and CE standards.

This model is ideal for regulated workshops, structured industrial facilities, or companies implementing active safety procedures.

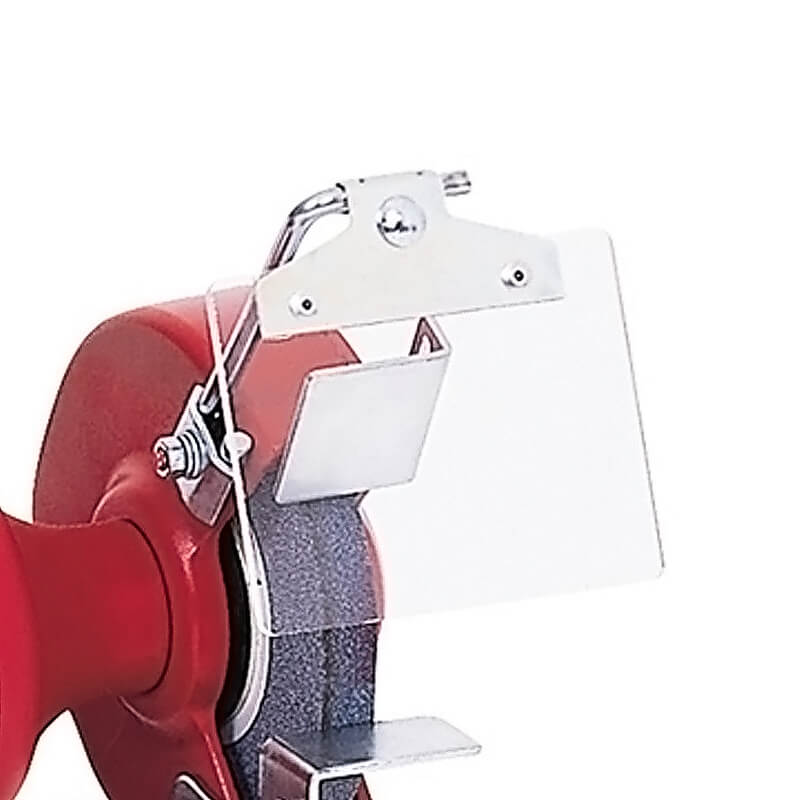

The MSB-GA10 is a set of two universal bench grinder safety shields that are extremely quick and simple to install.

Its straightforward design allows rapid upgrades of existing grinders without complex modifications, providing effective protection against sparks and debris while maintaining clear visibility.

Perfect for economical and efficient safety improvements, and a great choice for quick upgrades without changing your machine setup.

The MST-MA02 is a compact frontal safety guard designed for single bench grinders.

Equipped with a wide shock-resistant shield and a fast adjustment friction articulation, it provides effective protection while remaining easy to reposition daily.

It is an excellent choice when interlocking is not required and a simple, compact solution is preferred. Perfect for everyday workshop use where simplicity matters most.

PRISMONT provides a complete range of bench grinder safety guards designed to:

Beyond our products, we also offer turnkey support including installation service, maintenance service, and custom design solutions, along with technical guidance to help meet safety compliance requirements.

Need help choosing the right model? Our team is here to assist you. Contact our team today and we’ll help you select the safest solution for your bench grinder station.