Perform sanding, belt sanding and polishing operations on metal lathes safely and in a controlled manner with PRISMONT sanding tools. Designed and manufactured in Canada, these original tools are built to replace manual sanding with a more stable, precise and industrially adapted solution. PRISMONT sanding tools are installed directly on existing lathe tool posts and deliver consistent finishes while improving operator safety.

Sanding, belt sanding, polishing and deburring operations are part of everyday work on lathes in many machine shops. When performed manually, these operations can be difficult to control, vary from one operator to another and unnecessarily expose workers to hazardous zones around rotating parts.

PRISMONT sanding tools were developed to transform this critical step into a safer, more controlled and more consistent operation. By keeping the abrasive away from the operator’s hands and offering precise control over pressure and contact area, these tools make it possible to move away from manual methods toward a solution specifically designed for industrial turning.

The PRISMONT sanding tool range is built around two complementary solutions, each designed to meet specific finishing needs on lathes.

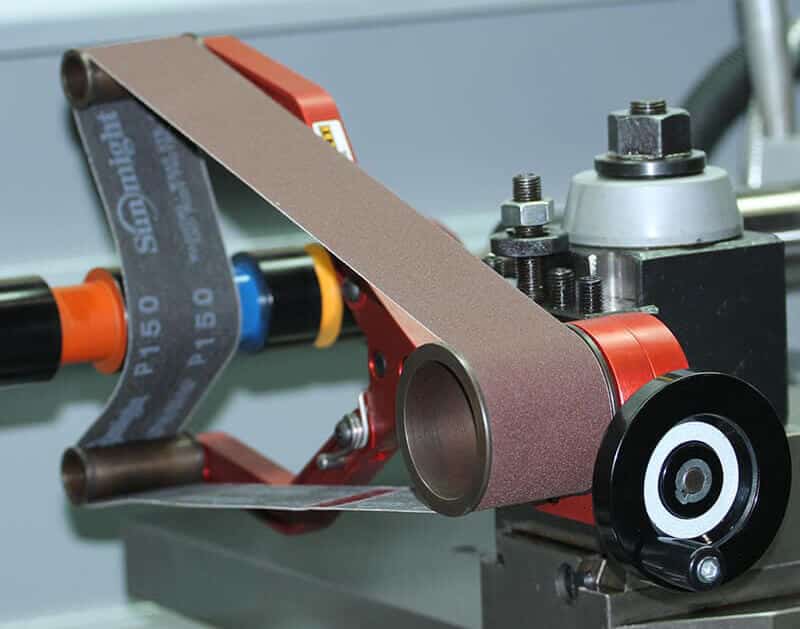

The MST-SBH lathe sanding belt holder is designed for sanding, belt sanding, polishing and deburring operations on the external surfaces of turned parts. It allows stable and uniform work on rotating parts while maintaining excellent control over applied pressure.

Available in multiple sizes, the MST-SBH adapts to a wide range of part diameters and working conditions. The standard model offers safe manual operation, while the MST-SBH(A) version integrates a belt clutch control mode that helps control rotation during finishing operations.

The MST-IPA inside polishing attachment for lathes is specifically designed for polishing, rectification, sanding, and deburring operations inside hollow parts such as tubes.

Its design allows access to hard-to-reach areas while maintaining a high level of precision and safety. Offered in different lengths, diameters and power, the MST-IPA adapts to a wide range of industrial applications, both in production shops and technical training environments.

All PRISMONT sanding tools are designed to be installed directly on existing lathe tool post already in place on the machine. This approach allows fast commissioning without complex machine modifications or additional equipment purchases. Designed for conventional and CNC lathes.

Associated abrasive accessories are also quick and easy to replace, minimizing downtime and helping maintain a steady production rhythm.

In addition to sanding tools, PRISMONT offers abrasive accessories specifically designed to work with its tool range, including:

Available in various grits and dimensions, these accessories allow precise adjustment of the tool according to the application and desired finish level.

PRISMONT sanding tools are designed to meet the demands of industrial environments and recognized machine safety practices. The MST-SBH and MST-IPA models comply with international standards EN 12840:2001 and ISO 23125:2010, applicable to machine tools and turning equipment.

Manufactured from high-quality materials and designed for intensive use, these tools stand out for their durability. The robustness and consistency of PRISMONT tools ensure a long service life, even under demanding production conditions.

PRISMONT is the original manufacturer of these lathe sanding tools. Designed and manufactured in Canada, they have become recognized references in many machine shops, training centers and specialized industrial environments worldwide.

By choosing PRISMONT, you select an original, reliable and durable solution developed by an industrial safety specialist and designed to improve operator safety, finishing consistency and overall efficiency on lathes.